Enovix Corporation, the developer of next-generation 3D Silicon lithium-ion batteries, has announced the introduction of BrakeFlow, an intra-cell system that is claimed to significantly increase tolerance to thermal runaway from internal shorts without compromising energy density.

“When we founded Enovix in 2007, our approach to improving cell performance was unique from other advanced battery technology companies,” said Harrold Rust, co-founder, president and CEO of Enovix. “Solving a big problem differently than others is inherently challenging and creates unique issues. At the same time, it avoids problems others face and enables new opportunities others can’t exploit or even imagine. Today’s announcement is a momentous day for Enovix. It’s a great example of how taking a different approach can lead to game-changing technology.”

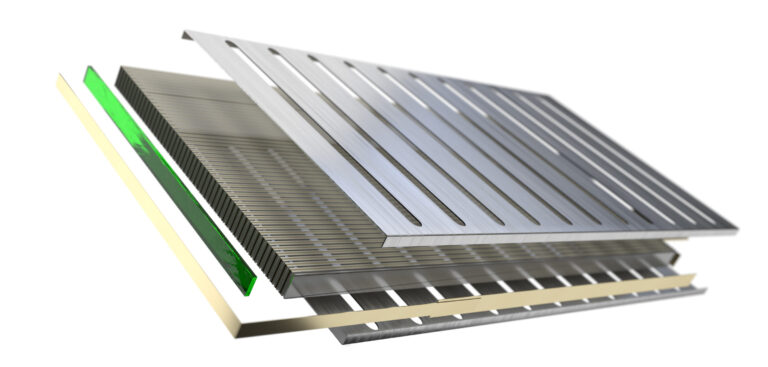

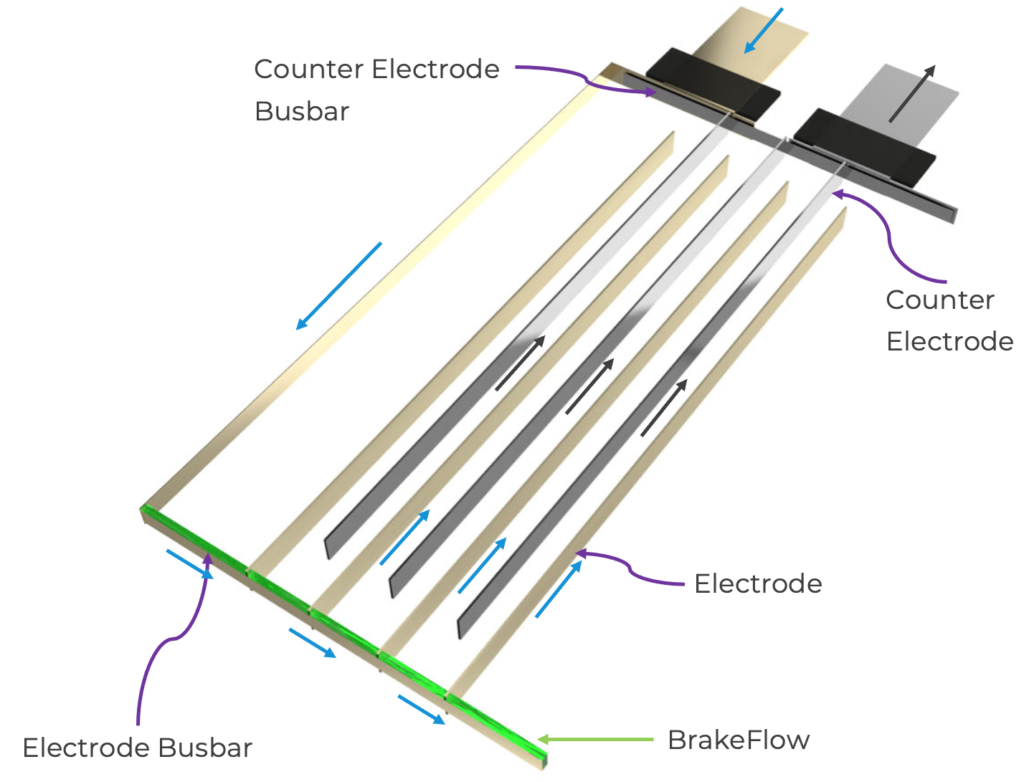

Unlike conventional ‘jellyroll’ Li-ion cell architecture, where energy density and safety can conflict, the Enovix 3D cell architecture incorporates multiple intra-cell features to improve electrical, physical and environmental abuse tolerance over conventional wound Li-ion cells.

The Enovix 3D cell architecture enables multiple parallel cell-to-busbar connections, which allows the addition of the BrakeFlow feature (shown in green in the illustration). The BrakeFlow incorporates a resistor with a set value at the busbar junction. During normal operation, each electrode carries a small current; however, in the event of an internal short, BrakeFlow regulates current flux from other areas of the battery to the short, thus limiting overheating in the short area and inhibiting thermal runaway.

“We believe our battery architecture is one of the most significant advancements in Li-ion battery design in decades,” added Ashok Lahiri, co-founder and CTO of Enovix. “Not only does our architecture enable a 100% active silicon anode, which notably increases energy density, but it also enables us to launch new innovations like BrakeFlow, which by design reduces the temperature rise at a short location, adding exceptional tolerance against thermal runaway.”

“BrakeFlow ushers in a new level of safety in Li-ion battery design,” concluded Cam Dales, GM and chief commercial officer at the company. “Adding BrakeFlow can significantly limit overheating during an internal shorting event, which is the primary cause of thermal runaway. Additionally, the mechanical robustness of our cell architecture allows customers designing for rugged environmental conditions to choose our high-energy-density pouch cells over lower-energy-density prismatic cells. This is just another example of what sets us apart from other advanced Li-ion battery manufacturers.”